A sand filter septic system is a type of wastewater treatment system that uses a bed of sand to filter out contaminants and treat wastewater.

It is typically used in areas that have little/no soil or where a leach field has previously failed for whatever reasons.

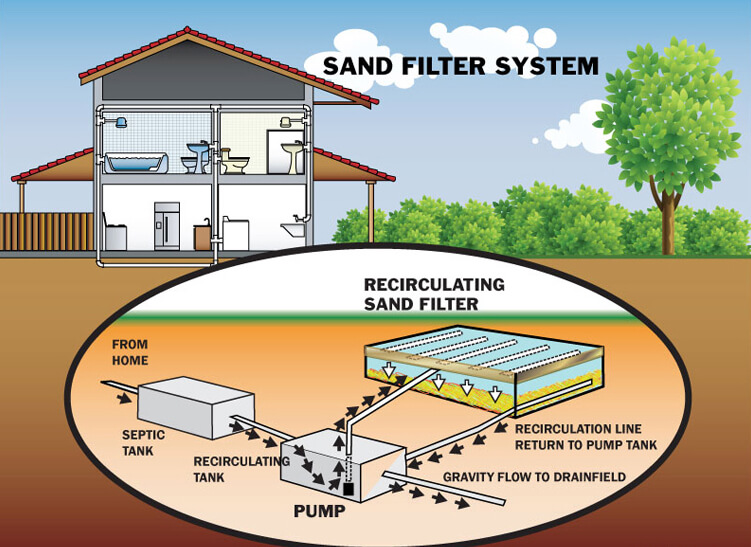

A sand filter system is made up of a septic tank, a sand filter, a pump chamber, and a leach field.

How Does The Sand Filter Septic System Work?

A sand filter septic system works by passing wastewater through a bed of sand and gravel, which removes contaminants and treats the wastewater before it is discharged into the soil.

This process typically happens in a couple of steps:

- Wastewater leaves the house through the plumbing and enters the septic tank where any grease floats to form the scum layer while the solids sink to form the sludge layer. Anaerobic bacteria will then start digesting the solid waste thereby liquefying it. This is the first step of treatment and is also known as primary treatment.

- The liquefied waste then flows into the pump chamber, in readiness to be pumped into the sand filter bed. At this stage, the effluent is also treated as it passes through the layers of gravel.

- Depending on the system, some designs have a tertiary filtration stage. This usually entails the killing of pathogens in the effluent through UV disinfection.

The trenches are typically lined with sand that has a healthy bacteria colony and these bacteria help to purify the wastewater by breaking it down further.

For the system to work well, the effluent needs to be distributed in the trenches in equal doses and that is typically done by the pump chamber.

The pump chamber uses a timed dosing mechanism to limit the number of doses to anything from 4-18 doses daily depending on the system design.

Once the effluent has been treated by the bacteria in the trenches, it percolates into the soil below the sand bed where it goes through the final treatment before getting into groundwater.

Source: Bannon Engineering

How Deep Do The Sand Filter Trenches Need To Be?

According to EPA guidelines, the filter beds should be 24 inches deep.

However, the excavation should be 3-4 feet deep to give allowance for the graded media that will be used in the trenches.

A minimum infiltrative surface area must also be taken into account when installing the system.

This figure can be arrived at by dividing the estimated flow rate by the estimated hydraulic loading rate.

Bottomless Sand Filter Septic System

A Bottomless Sand Filter (BSF) system is a type of sand filter that uses media that is less uniform and that has a finer texture.

BSF systems do not have underdrains or bottom filter lines.

BSF systems have a higher hydraulic loading rate and are therefore designed a bit differently.

For starters, the top 24 -30 inches of the filter is placed above the ground surface.

Even though BSFs can be installed in any soil type, they are best used in locations that have shallow and limiting conditions.

A BSF will treat wastewater to a high degree of quality by the use of intermittent pressure dosing that is based on a timer as opposed to a need/demand basis.

This is typically achieved through a float-operated pump.

Sand Filter Septic System Pros and Cons

Pros:

- Perfect for locations that have poor soil conditions (e.g. a shallow soil depth or a region with high clay content).

- There are several designs to choose from

- Sand filter systems can be sued to revitalize a failed system

- They are applicable both for individual and community systems

Cons

- Installing sand filter systems may cost more than installing a basic conventional system

- Sand filter systems may require professional maintenance more regularly than conventional systems

- The design specifications require media of a specific size which may be hard to come by in some regions

- The system requires electricity to run the pump which can be a challenge in remote and off-grid locations

Sand Filter Septic System Problems

The size of the media used is one of the main reasons for the possible issues with sand filter septic systems.

If the media used is larger than the recommended size, the water will pass through too fast. This means the water will percolate through the soil before it is sufficiently treated and that can cause groundwater pollution.

On the flip side, if the media used is too fine, the rate of flow will decrease too much which can result in leakage as well as increase the changes of clogging.

There is also the danger of clogging as a result of excess grease and solids coming from the tank and getting into the sand filter beds.

Sand filter beds should be maintained by a trained professional every 6-12 months to catch any possible issue before it is too late.

If this doesn’t happen, the pump, distribution box, or one of the other components may fail and it might call for expensive repairs.

Sand Filter Septic System Maintenance

As a sand filter septic system owner, you are responsible for its maintenance.

Some of the regular maintenance tasks include:

Regular inspection

You should inspect your tank for sludge and scum accumulation every year.

As a rule of thumb, this inspection should be done by a skilled septic tank professional.

Never attempt to open the septic tank on your own as it may expose you to the toxic gases that are contained in the tank.

In some regions (e.g. Oregon), the law requires you to maintain a service contract with a duly licensed septic system professional.

This is a measure to ensure you continue with the required regular inspections.

Maintenance

Pumping your tank regularly is one of the most important maintenance tasks.

Due to the delicate nature of sand filter systems, you shouldn’t wait until the tank is full for you to empty it.

As a rule of thumb, you should pump your tank when the solids accumulate to 35% of the tank.

Depending on your location, you may also be required by law to pump your tank at least once every 2-3 years.

In addition to pumping the tank, you may also want to check the components of the system at least once a year.

For instance, it’s important to ensure the alarm is operational, which you can do by lifting each float switch in the pump chamber.

It is also recommended to keep a record of your pumping schedule as well as your pump-cycle volume.

How Long Do Sand Filter Septic Systems Last

Sand filter septic systems, just like any other system, will not last forever.

That said, a well-installed and properly maintained system can last for 20-50 years depending on several variables.

For instance, a septic system that uses a steel tank will last for 15-20 years whereas one that is made of plastic can last for up to 40 years.

The vegetation around the system may also affect the lifespan of the system.

If some shrubs or trees have an intrusive root system, there is a chance considerable damage will be done to the septic system thereby limiting its longevity.

However, maintenance is arguably the most important factor. For instance, controlling the amount of water sent into the tank will help prevent hydraulic overload which is detrimental to the health of the system.

Also, pumping your tank regularly will prevent system failure.

These are just a couple of examples but by and large, a system that is maintained well will last longer than one that is abused or neglected.

Also, even though the entire system may last for decades, the sand filters and other components may only be good for a couple of years.

That is why the system must be inspected regularly to replace any worn-out parts.

Can A Sand Filter Septic System Be Used For Commercial or Industrial Applications?

The simple answer is yes – sand filter systems can also be used for industrial and commercial applications.

However, the design, as well as the application, maybe a bit different from domestic systems.

In industrial scenarios, sand filters may be incorporated into the wastewater management system to help in the recycling of wastewater.

In fact, it is standard practice to use sand filters for the removal of suspended solids in industrial filtration systems.

In some cases, sand alternatives like anthracite and gravel may also be used.

Image sources: 1, 2, 3